Spinner II® Oil-Cleaning Centrifuges

The world leader in bypass filtration for heavy-duty diesel engines

Spinner II centrifuges have provided exceptional oil-cleaning performance and improved engine reliability for more than two million diesel engines worldwide. They have been installed as standard equipment by more than 40 engine manufacturers, including Alco, Caterpillar, Cummins, Detroit Diesel, EMD, General Electric, Mack, Navistar, Waukesha, White Superior, and many others. Spinner II oil-cleaning centrifuges may be specified on new equipment or easily installed on existing engines.

Capacity + Constant Efficiency

A Spinner II centrifuge has up to 10 times the debris-holding capacity of even the best filters. So it stays on the job longer. And because the centrifuge removes contaminants from the oil stream—instead of accumulating them in the oil or on a filter surface—there’s less to plug. Cleaning efficiency remains constant over the entire service interval. In addition, the Spinner ll is a Green product—with no EPA requirements for contaminant disposal.

Clean Oil Means Savings

Cleaner lube oil reduces the contaminants trapped in the engine’s main oil filter(s). Keep in mind that service intervals vary by application, engine duty cycle and other factors. Spinner II recommends that you consult with your lube oil supplier, engine manufacturer or distributor and lube oil testing service before making any decisions about extending oil drains.

Extend Routine Service Too

Regardless of how often you change your oil, you won’t have to service your Spinner II centrifuge as often as you change ordinary filters. In many applications, Spinner II centrifuges remain in service for a year or more. That’s because there’s no clogged filter media to clean or replace. Instead, the Spinner II centrifuge removes contaminants and stores them away from the oil stream in a high-capacity, cleanable bowl. Actual service intervals will vary with duty cycle.

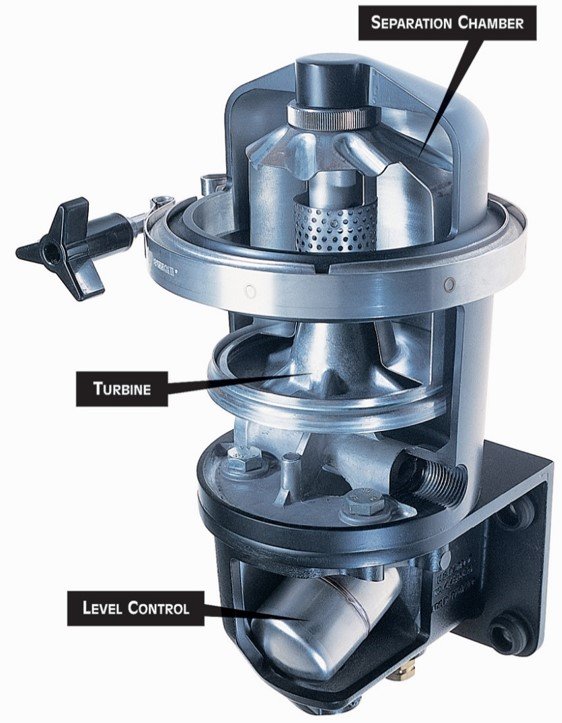

How it works

The Spinner II centrifuge is a highly efficient bypass filtration device. It diverts a small side stream of oil for processing and returns clean oil to the crankcase. Powered only by engine oil pressure, the centrifuge operates at speeds in excess of 6,000 rpm, generating a force more than 2,000 times greater than gravity. This force slings contaminants smaller than one micron out of your oil and packs them into a dense cake on the wall of the cleanable centrifuge bowl. A Spinner II centrifuge flows up to two gallons of oil every minute, allowing it to clean the entire sump capacity of a typical heavy-duty engine 10-15 times an hour.

Spinner II is a registered trademark of TF Hudgins, Inc.