Models

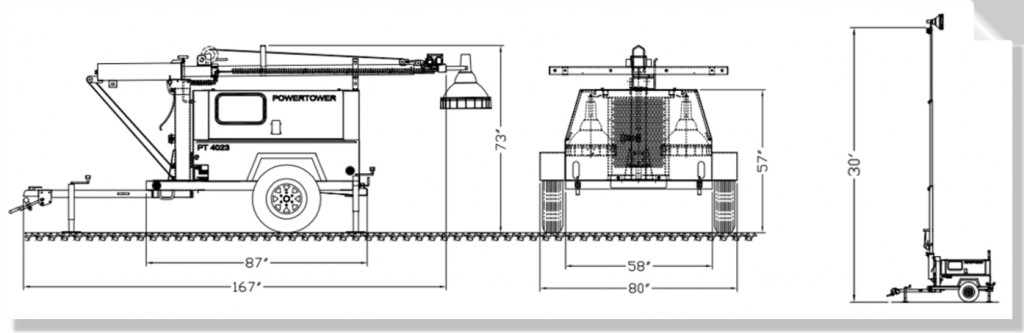

PowerTower PT4023

(23 kWe standby, 21 kWe prime power)

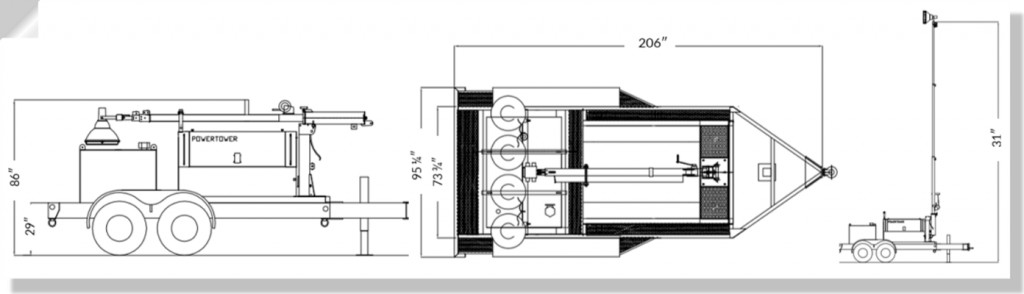

Extreme Duty PowerTower PT4023XD

(23 kWe standby, 21 kWe prime power)

Extreme Duty PowerTower PT4030XD

(30 kWe standby, 28 kWe prime power)

Checklist of Things to Consider

Checklist of Things to Consider

Standard Features

Here is a list of some of the standard features, including those that set us apart from the competition.

Versatility

- Available as a portable lighting tower and an AC generating set.

- Generator outputs from 6 to 30 kWe.

- Available with a variety of distribution and lighting options.

Durability

- 14 gauge, powder coated container.

- 14 gauge aluminum checker plate on front of canopy and front rail..

- Galvanized mast.

- Stainless steel hinge assembly.

- Simple, easy to repair and replace components.

Extreme Climate Capabilities

- Dual control cooling system outperforms other machines in cold climates and in high ambient temperatures.

- Glow-plug preheat system for improved cold-weather starting.

- Designed and built in northern Alberta.

Lights

- Metal halide lamps (optional LED lamps).

- High-efficiency light fixtures provide uniform light pattern.

- Light stowage inside the canopy to prevent damage during transportation or vandalism while the machine is unattended.

- Heavy duty lens guards.

Light Mast

- One of the tallest masts in the industry at 30 plus feet.

- Easy adjustable for all-around coverage.

Safety and Security

- Light stowage inside the canopy to prevent damage during transportation or vandalism while the machine is unattended.

- Safety shutdowns for low oil pressure and high coolant temperature.

- Lockable, weather-resistant access doors.

- Transport Canada’s National Safety Mark certified trailer.

Control

- Control panel features elapsed hour meter.

Environmentally Responsible Construction

Sealed, 14 gauge containment pan under the engine/generator and fuel tank to provide an extra margin of safety against environmental contamination.

Model Specifications

| Features | PT4023 | PT4023XD | PT4030XD |

|---|---|---|---|

| Engine and Generator | |||

| Standby (Prime) electrical power (kWe) | 23 (21) | 30 (28) | |

| Engine model | Kubota | ||

| EPA Tier | Tier 3 and Interim Tier 4 | ||

| Mechanical power kWm (hp) |

24.5 (32.8) | 31.3 (42) | |

| RPM (continuous duty) |

1800 | ||

| Alternator |

|

|

|

| Auxiliary electric cooling fan |

Supplemental electrical fan provides cooling in all climate conditions. |

||

| Vibration isolators | Yes | ||

| Block heater | Yes | ||

| Features | PT4023 | PT4023XD | PT4030XD |

| Control Panel (CSA Approved Construction) | |||

| Engine controls |

|

||

| AC distribution |

|

|

|

| Features | PT4023 | PT4023XD | PT4030XD |

| Mast | |||

| Lamps |

|

||

| Light coverage | 5 to 7 acres (2 to 2.8 hectares) | ||

| Extension |

|

||

| Degrees of rotation | 350° | ||

| Double winch, tilting and raising system |

|

||

| Canopy | |||

| Container |

|

||

| Light storage |

Internal light storage with pin locks. |

||

| Access doors |

|

||

| Lifting | Unit lifting eye. | ||

| Window | 18″ x 11″ window in control panel door. | ||

| Features | PT4023 | PT4023XD | PT4030XD |

| Trailer | |||

| Safety certification |

|

||

| Frame | 89 mm × 63.5 mm (3.5″ × 2.5″) tubular construction. |

|

|

| Weight capacity | 3,500 lbs. with Tor-Flex axle |

|

|

| Brakes | Electric | ||

| Wheels | 15″ white spoke wheels. | 16″ white spoke wheels. | |

| Fuel tanks | 2 × 95 litre (2 × 21 imperial gallon) internal fuel tanks with gauge. |

|

|

| Hitch | Hitch with pintle/ball. | 6 hole adjustable hitch with pintle/coupler. | |

| Jack | Front leveling jack. | 8,000 lb drop let jack. | |

| Safety chain and hooks | Yes | ||

| Transportation tie downs | At each corner. | ||

Optional Features

Here is a list of our factory-installed options.

|

|